Quality control (QC) is a critical aspect of manufacturing that ensures products meet the required standards. In traditional QC processes, human inspectors manually check the products, but this method can be slow and prone to errors. However, thanks to advancements in artificial intelligence (AI) and machine vision, product inspection has reached new levels of accuracy and speed. This post will explore how AI is transforming quality control with machine vision, making it more efficient and effective.

What is Machine Vision?

Machine vision refers to a computer-based system that uses cameras, sensors, and image-processing software to capture and analyze visual data. These systems mimic human sight to identify objects, measure dimensions, and detect potential defects during production. Machine vision is a critical tool in modern manufacturing, offering significant improvements over traditional manual inspection methods.

Machine vision systems typically consist of the following:

- Cameras: High-resolution cameras that capture detailed images of the product.

- Lighting: Specialized lighting that illuminates the product to highlight potential defects.

- AI Algorithms: Artificial intelligence that processes the visual data and makes real-time decisions about the product's quality.

This automated visual inspection process has become an integral part of modern manufacturing quality control systems.

How AI Enhances Product Inspection with Machine Vision

AI makes machine vision better by making it smarter and better able to learn from its mistakes. Machine vision systems that AI drives can look at huge amounts of data in real-time, find patterns, and find problems that a person might not see right away. Let's look at some of the ways that AI and machine vision are changing the way that products are inspected.

Faster and More Accurate Inspections

One big benefit of using AI to check products is that it speeds up the process. Machine vision systems that AI powers can handle a lot of visual data much faster than a person could. In just a few fractions of a second, these systems can scan goods very quickly and find mistakes and problems. This speed means that production runs can go faster, which can make operations more efficient overall.

Moreover, these systems are not prone to fatigue like human inspectors, which can lead to mistakes and missed defects. AI-based inspections ensure consistent results with minimal chances of error, significantly reducing the risk of defective products being released into the market.

Key Benefits:

- Fast inspection process, reducing production time

- High accuracy and consistency in defect detection

- Reduced human error, leading to fewer quality issues

Advanced Defect Detection

Traditional quality control methods rely heavily on human perception to identify defects such as scratches, dents, and color inconsistencies. While humans are capable of detecting obvious flaws, machine vision combined with AI can detect minute defects that would typically go unnoticed. AI can analyze patterns, textures, and shapes in the image data and compare them against predefined quality standards.

AI systems can also differentiate between types of defects based on severity, enabling manufacturers to prioritize certain issues. For example, a minor scratch on a surface may be less critical than a broken part, and AI can flag these accordingly.

Key Benefits:

- Detects both large and small defects, improving overall product quality

- Helps in identifying defects that may be challenging for human inspectors to spot

- Prioritizes defects based on severity for more effective quality control

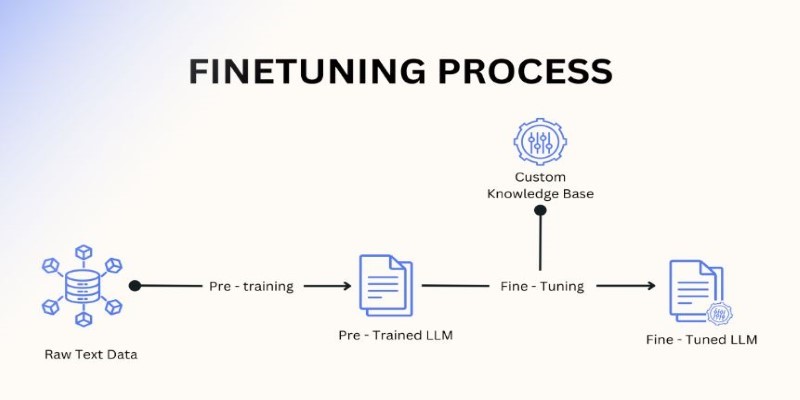

Continuous Learning and Adaptation

AI systems can learn and improve over time, making them increasingly valuable as production lines evolve. Machine learning algorithms allow the system to adapt to new product designs, variations in raw materials, and changes in production processes. This continuous learning capability means that AI-powered machine vision systems can handle a broad range of inspection tasks without requiring significant reprogramming.

For example, as a production line produces different variations of a product, the AI system can quickly adapt to recognize new defects or characteristics without human intervention. It makes AI-powered inspection systems scalable and flexible, allowing manufacturers to keep up with changing demands.

Key Benefits:

- AI systems continuously improve through machine learning

- Able to handle new product types or production changes without downtime

- Flexible and scalable to accommodate evolving manufacturing needs

Real-World Applications of AI and Machine Vision in Quality Control

AI and machine vision are being used across various industries for quality control and product inspection. Here are some examples of how these technologies are applied in real-world scenarios:

Electronics Manufacturing

In electronics manufacturing, even the smallest defect can render a product unusable. Machine vision systems equipped with AI can inspect PCBs (Printed Circuit Boards) for defects such as misalignment, missing components, or damaged parts. AI algorithms can detect these issues faster and more accurately than a human inspector, ensuring that only fully functional products make it to the market.

Example Uses:

- PCB inspection for missing or misplaced components

- Detection of soldering defects and shorts

- Visual verification of labels and barcodes on products

Automotive Industry

The automotive industry relies heavily on precise quality control to ensure that components are manufactured to exact specifications. AI-driven machine vision systems are used to inspect everything from engine parts to car bodies, checking for surface defects, dimensional accuracy, and assembly issues. These systems can also detect parts that are out of alignment or missing, preventing defective vehicles from reaching customers.

Example Uses:

- Inspection of car body panels for dents and scratches

- Measurement of part dimensions to ensure they fit together properly

- Detection of missing or misplaced components during assembly

Conclusion

AI-powered machine vision is revolutionizing the way quality control and product inspection are carried out in manufacturing. By offering faster, more accurate, and consistent inspections, these technologies help manufacturers produce high-quality products while reducing costs and improving efficiency. While challenges such as initial setup costs and integration complexities exist, the long-term benefits of AI in quality control make it a worthwhile investment for manufacturers aiming to stay competitive in a rapidly evolving market.